Here is a small selection of images of parts that we have made.

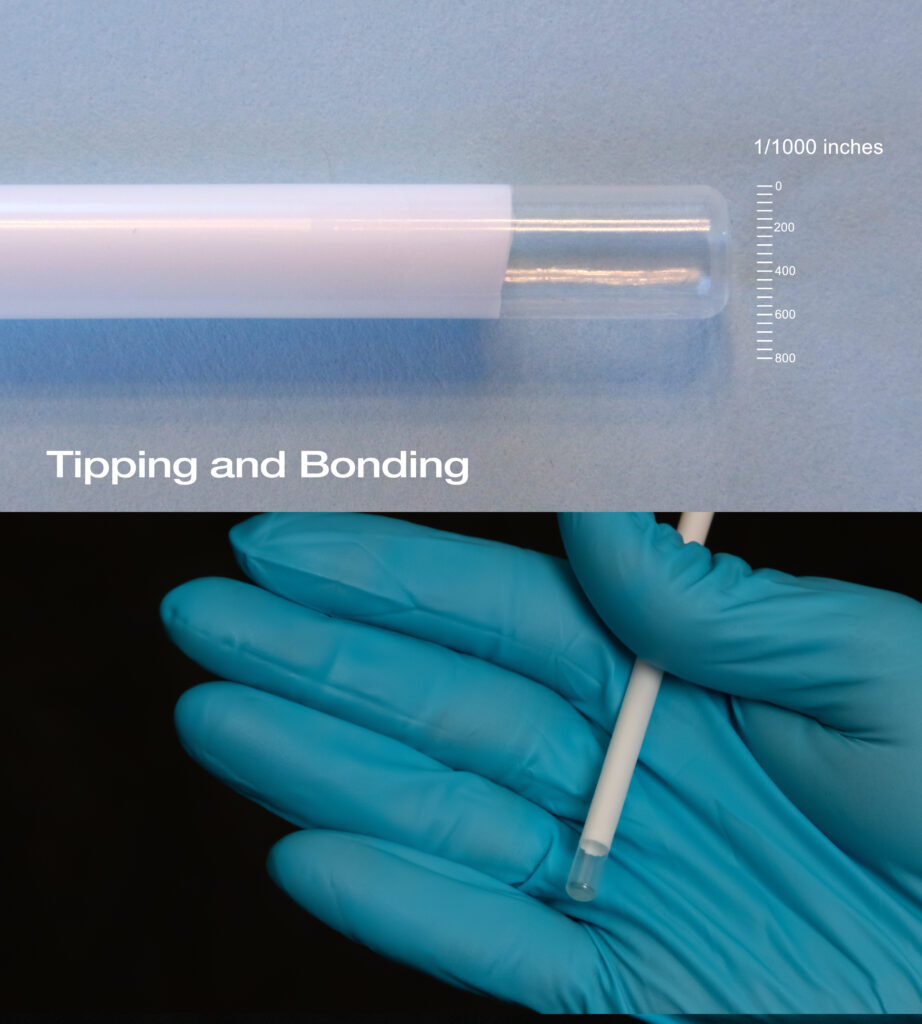

Pellethane ® loaded with TiO2, Propell ™ and strengthening additive thermally bonded to natural Pellethane ™. Tipping operation to seal end of tube to provide a-traumatic entry and maintain specified burst strength.

Shaped Polyimide. Forinno, LLC can reshape Polyimide. Create specific cross-section profiles, stepped polyimide, flared polyimide. Tight tolerance cutting services.

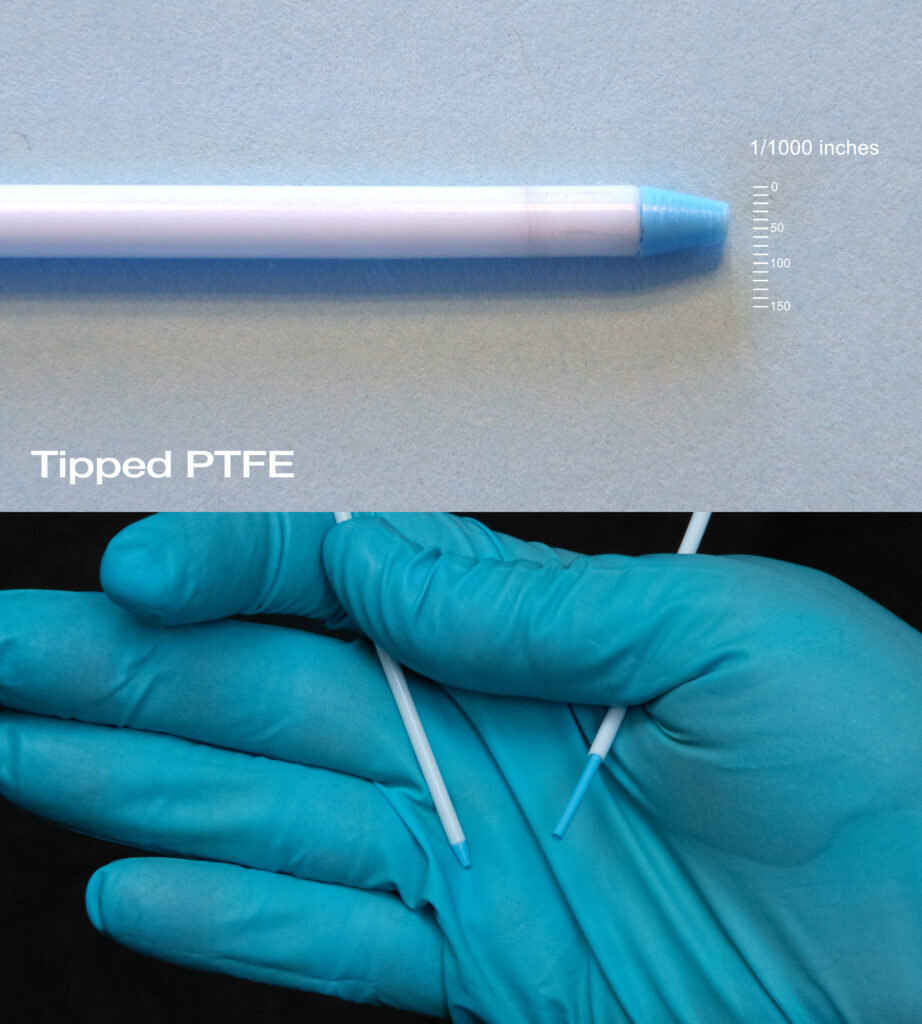

Top – Tungsten marker embedded in PTFE tube while forming a completely sealed end.

Bottom – Pure PTFE tip with spherical end capable of withstanding significant loads and pressure.

Lubricious FEP sheath with radiused tip to match tapered tip HDPE

Custom shape setting of all thermoplastics.

Top – Flared FEP tubing. Any wall. Any size.

Bottom – Thin walled natural FEP thermally bonded to thick walled colored FEP.

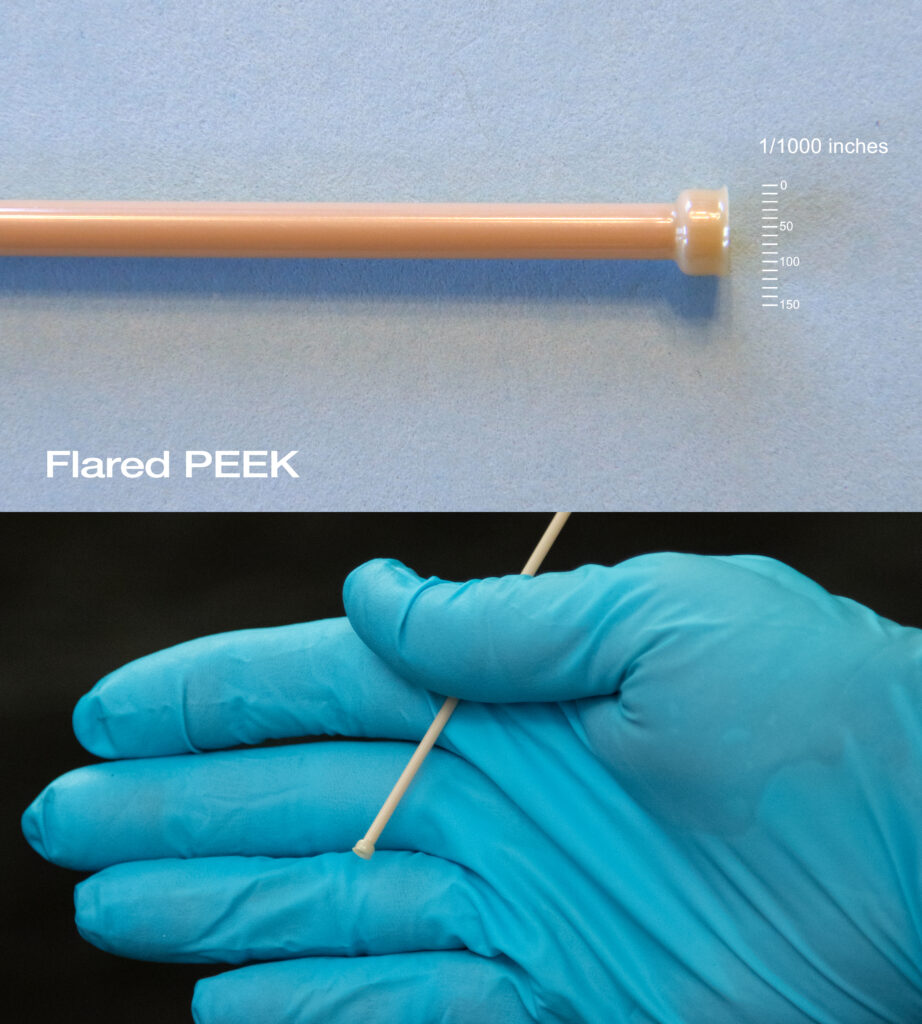

Forinno, LLC has specialized process controls to heat form complex shapes in various PEEK profiles.

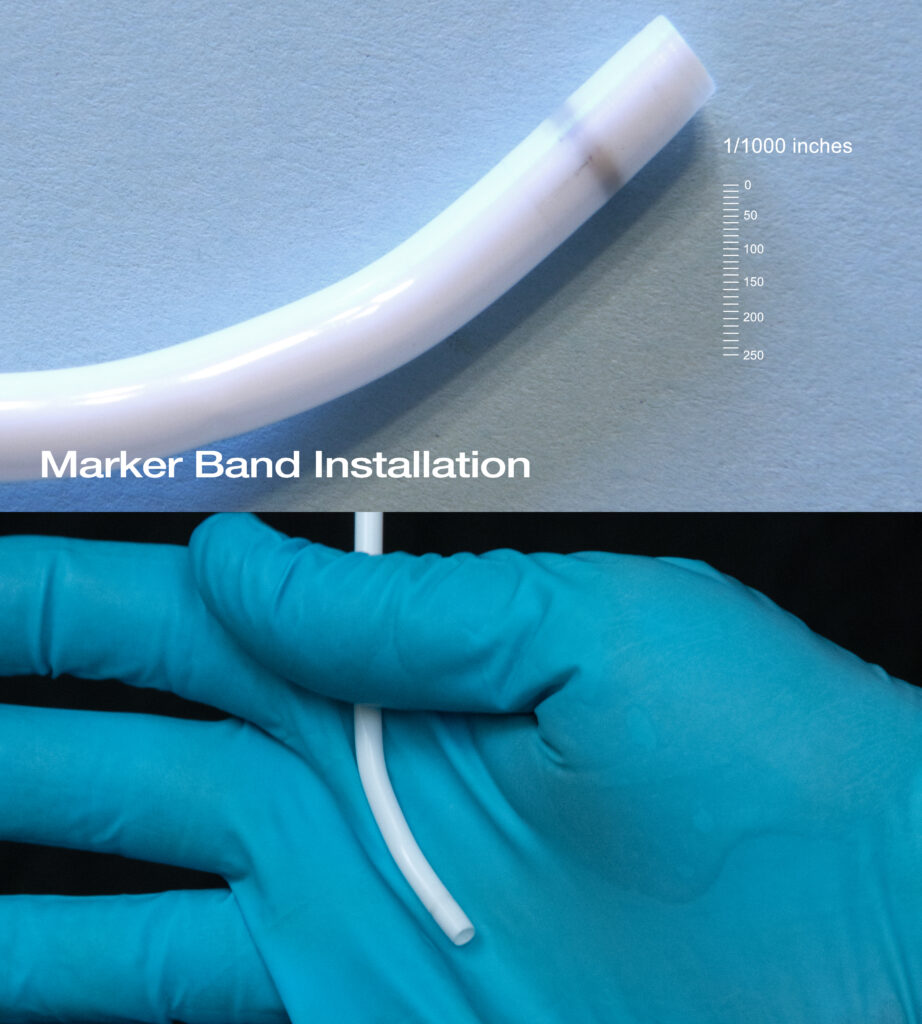

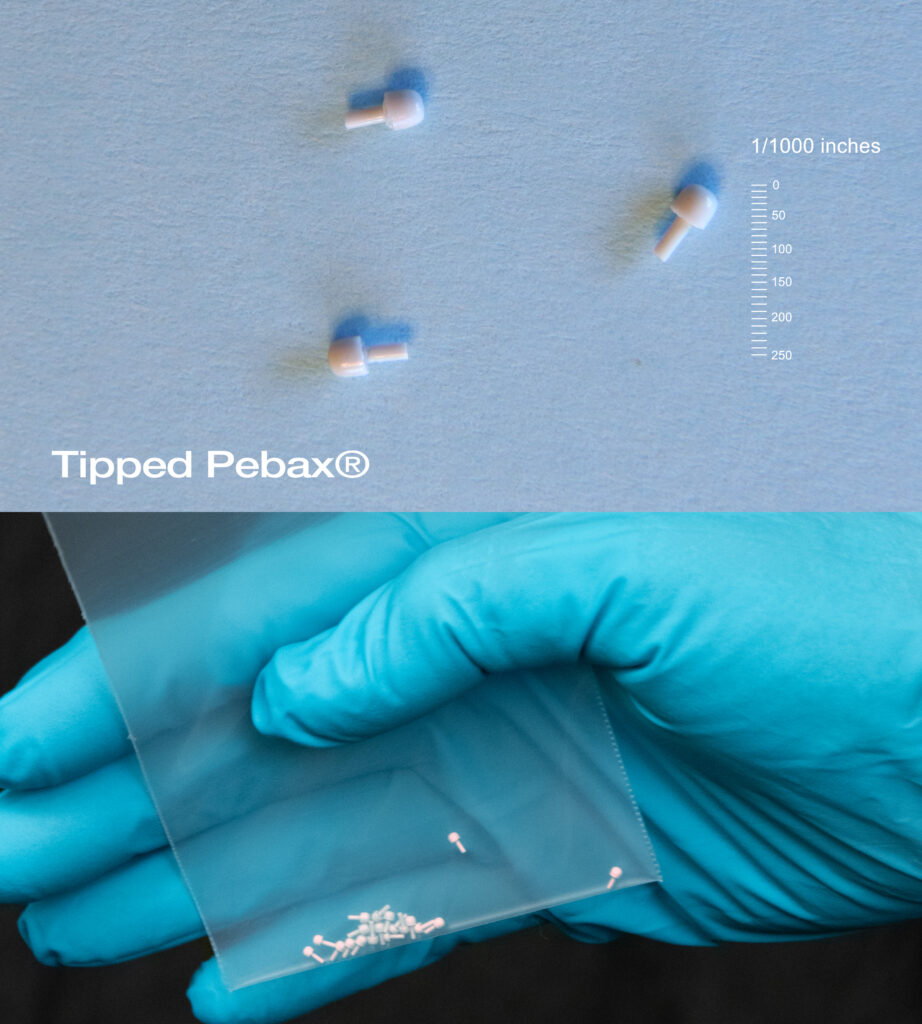

Platinum Iridium marker band thermally inserted into Pebax ®, a-traumatic tip, and custom shape set.

Flaring to your custom design on Fluoropolymers, Thermoplastics and Thermosets.

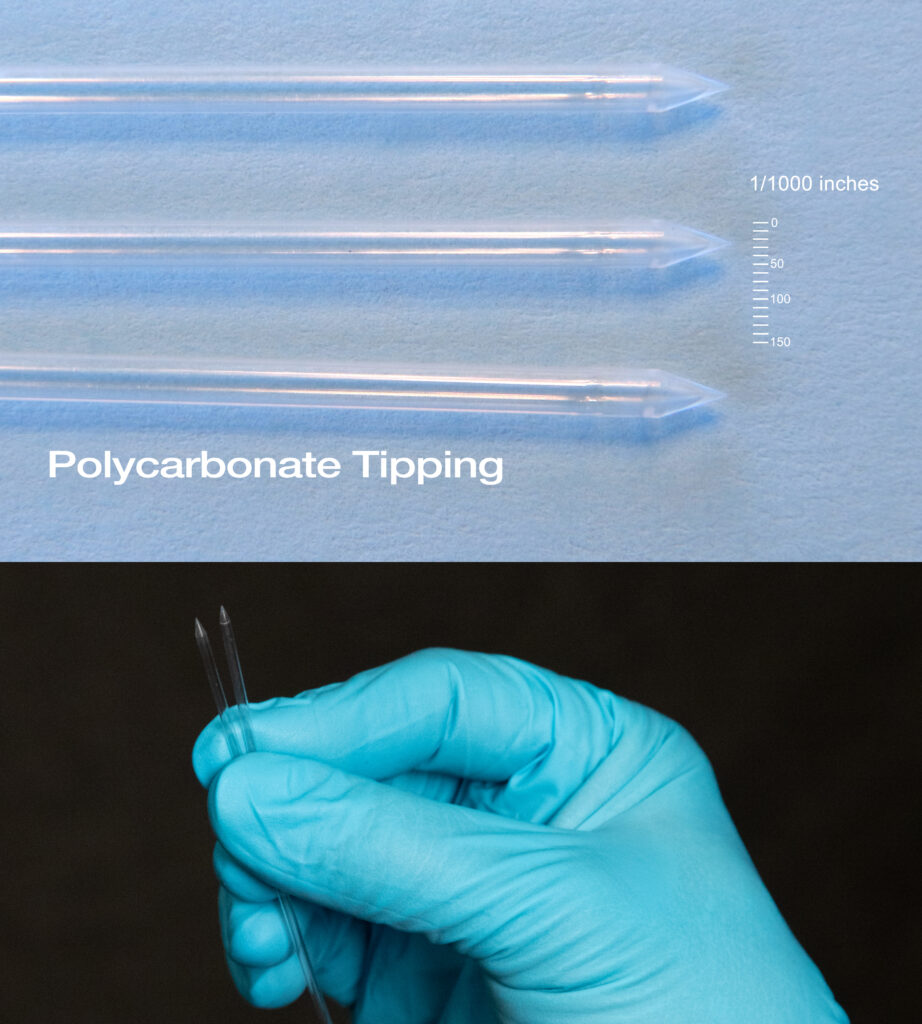

Long, smooth tapers can be made on low durometer to high durometer tubing 2 FR to 30 FR. 55D Pellethane ® and 35D Pellethane ® shown.

Sharp tipping on polymers to create piercing features.

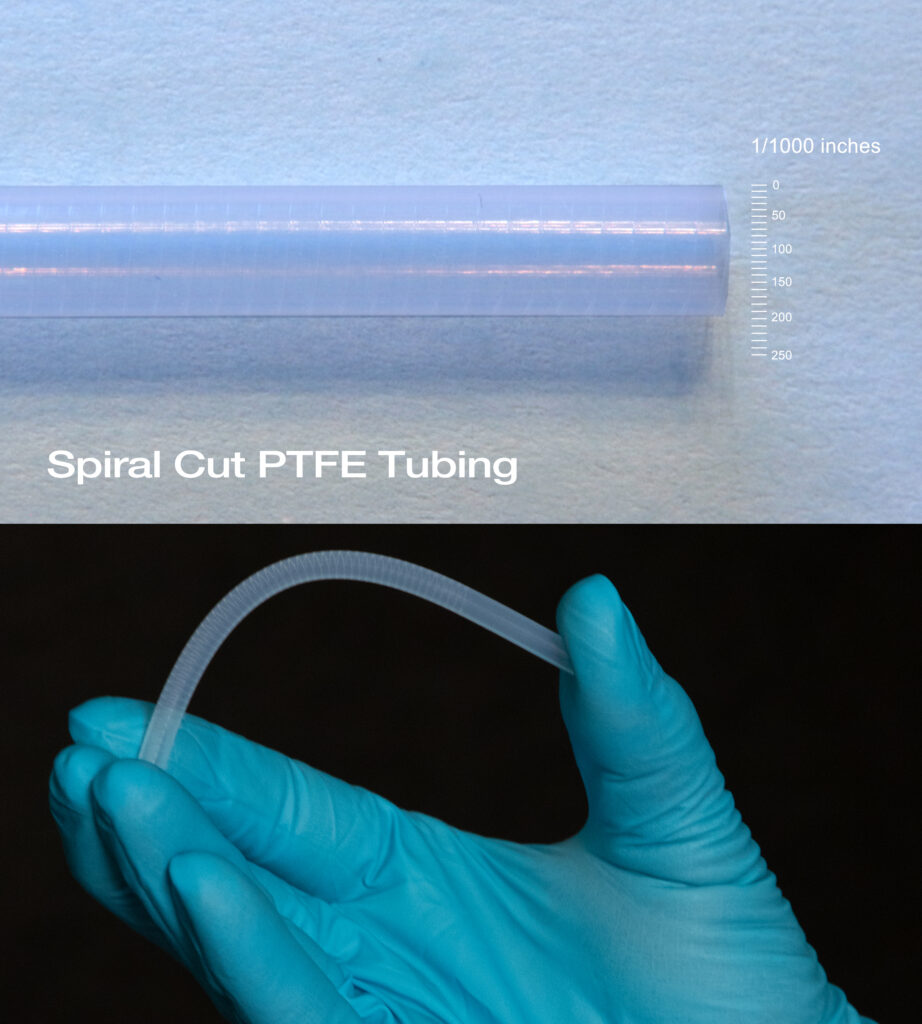

Forinno, LLC can spiral cut many different polymers. Partially cut or completely cut through the wall. Parts can be manufactured with consistent pitch or variable pitch.

Tube shaping in 2D or 3D.

Solid bead formed into large diameter with radius.

Tip forming and shape setting.

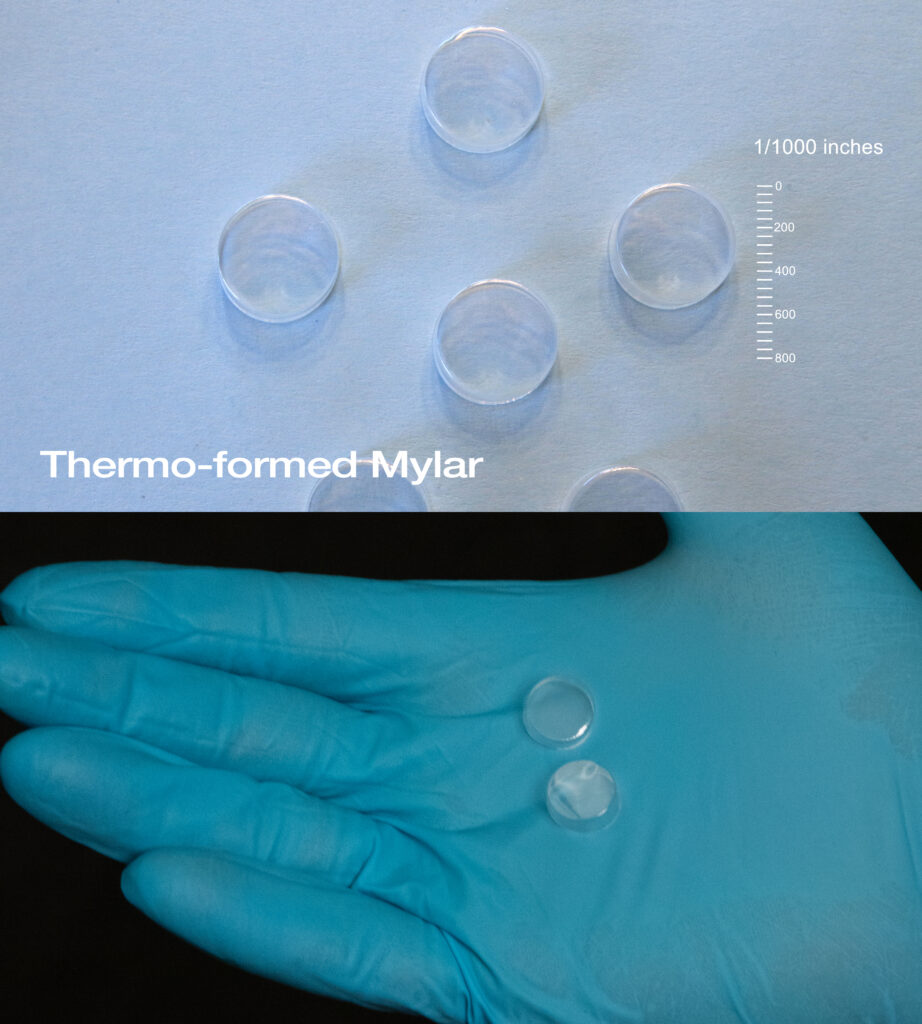

Mylar can be formed into various shapes in wall thicknesses from 0.005” to 0.015”

Angle cutting, skiving and custom cut profiles.

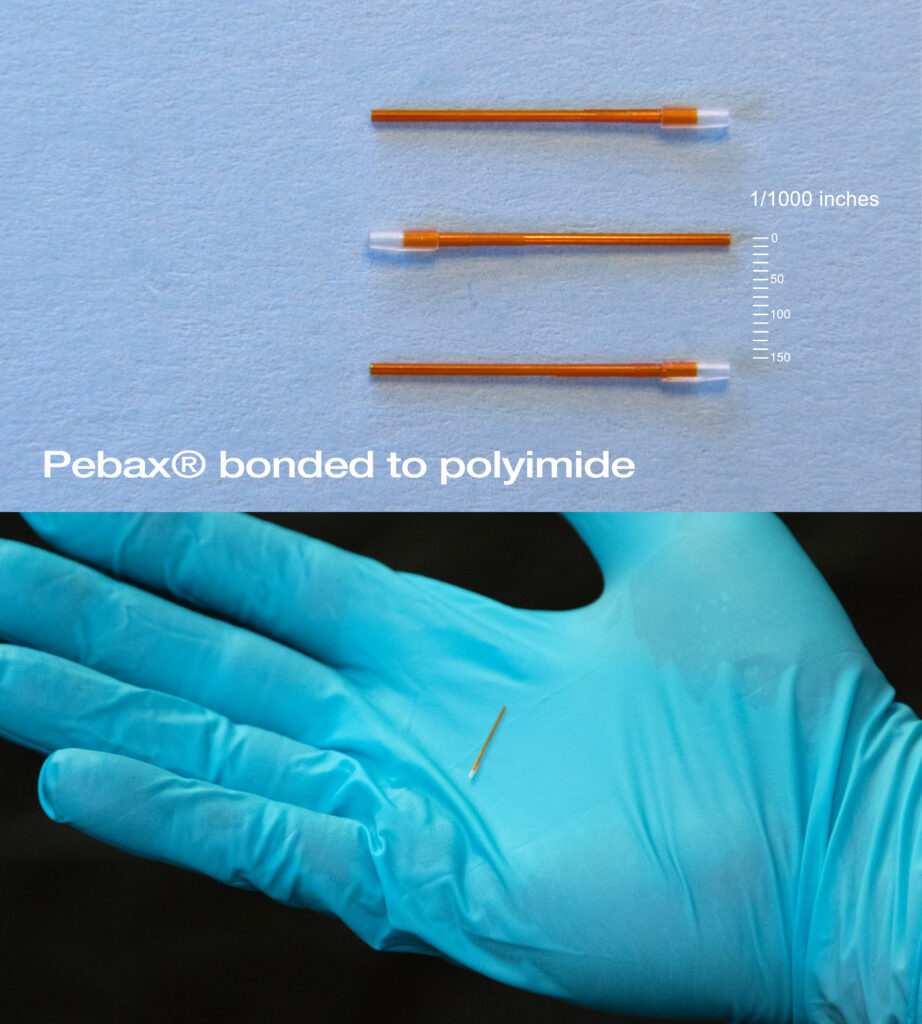

Our tipping and bonding processes can bond different durometer materials in addition to materials sometimes thought incompatible.

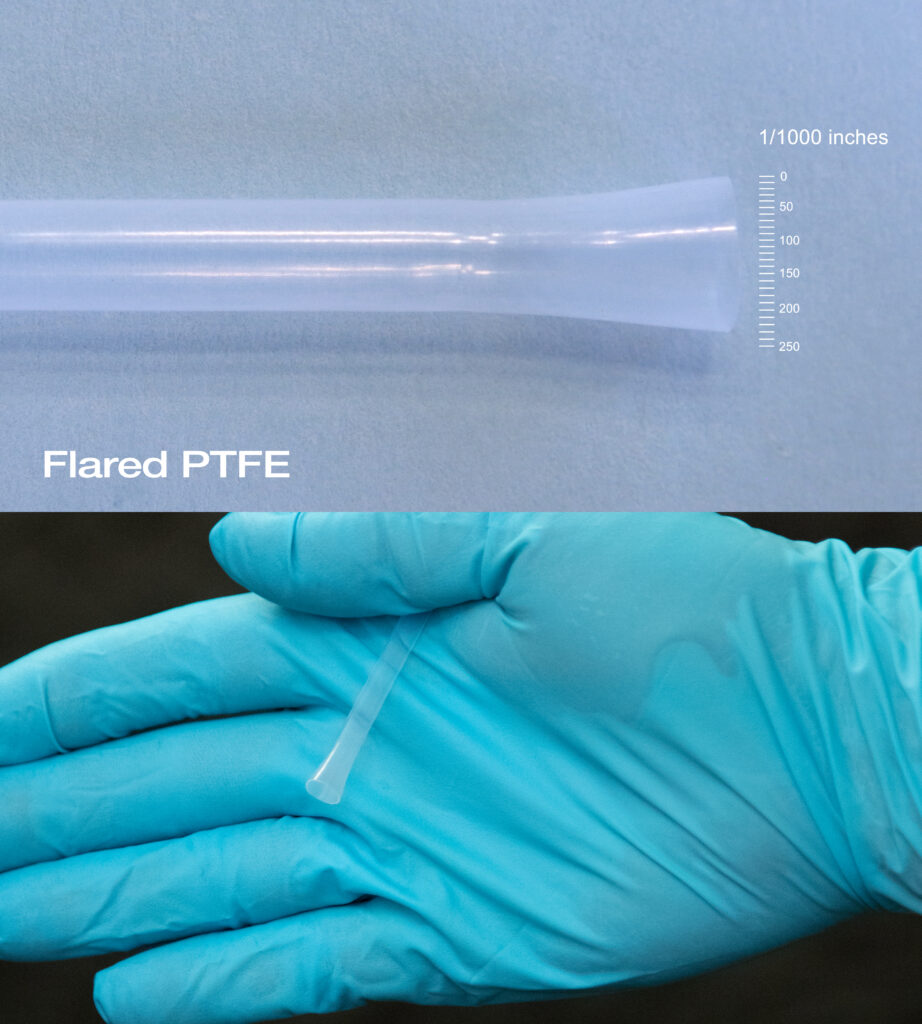

PTFE tubing can be flared or flanged at optimal process conditions to retain shape through various other heat operations.

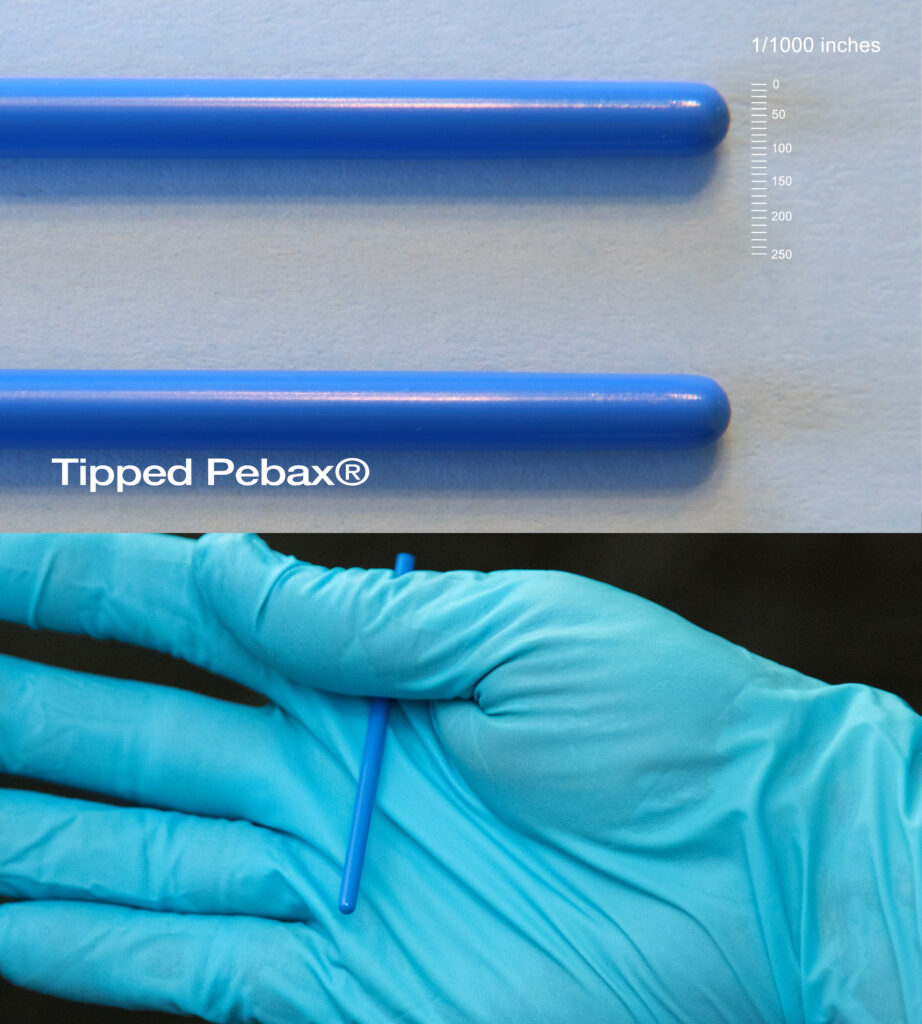

Closed end tipping made to any custom specification.

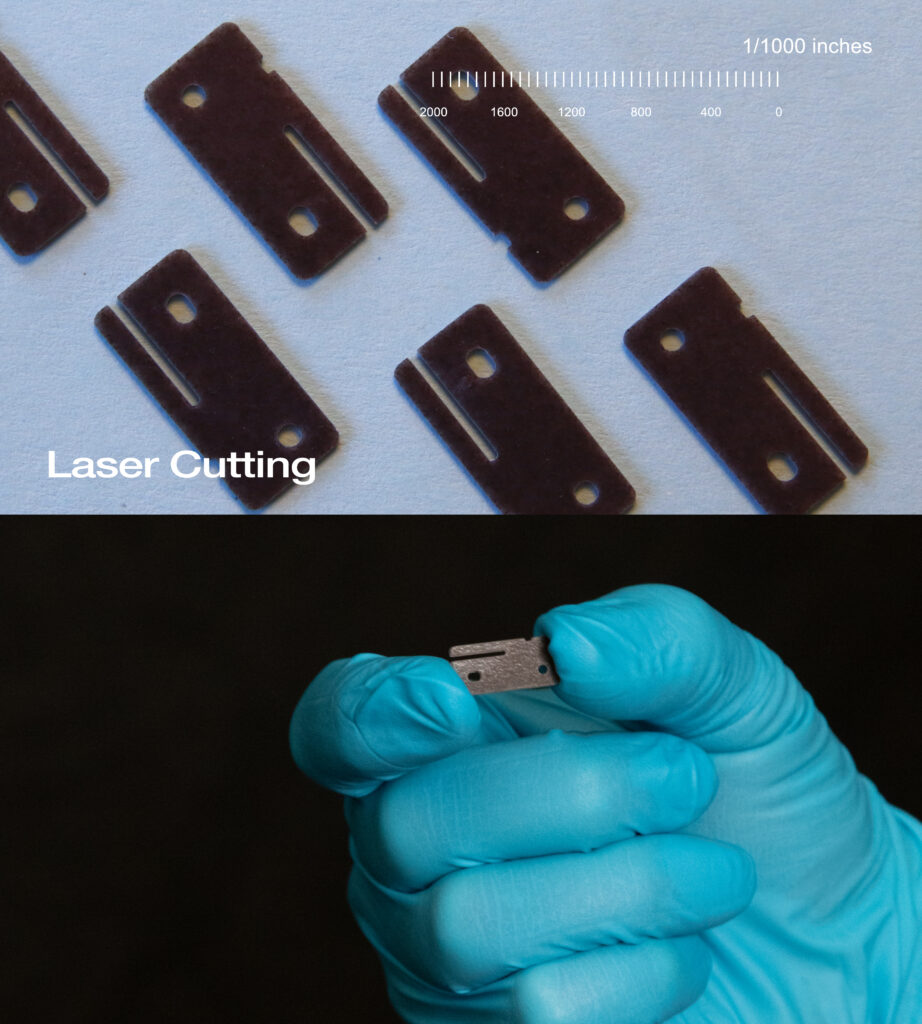

Slippery Delrin laser cut to customer’s tight tolerance requirements.

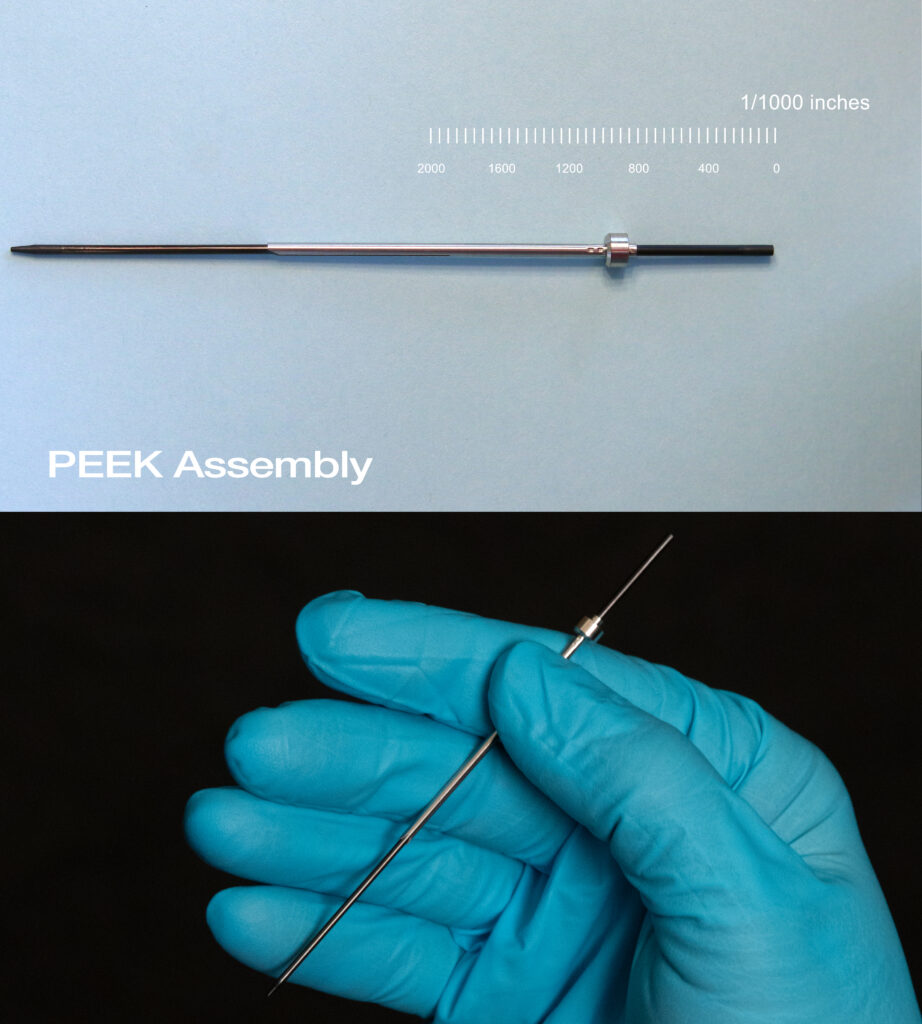

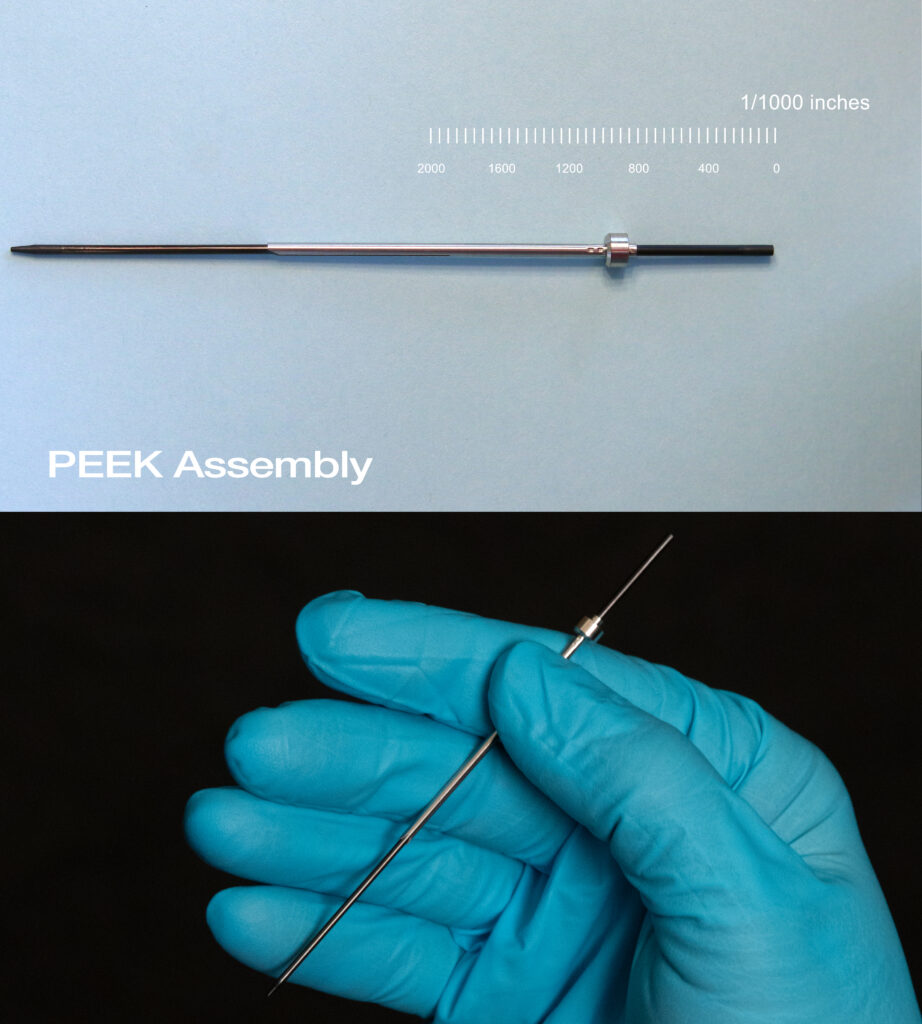

PEEK layered on inside and outside of Stainless Steel structure. Tipped on both ends to create a robust component capable of puncturing a surface repeatedly. This sample illustrates our tip forming, assembly and crimping capabilities.

PTFE is flared to create an easy entry for a device. Wire is embedded into tip via a thermo forming operation to securely hold the wire and create an a-traumatic tip on the distal end.

The flange on this tube was formed out of the tubing. The tip is forming can be done in virtually any shape. Hole drilling 0.015″ and up. Round, rectangular cut outs, and ovals.

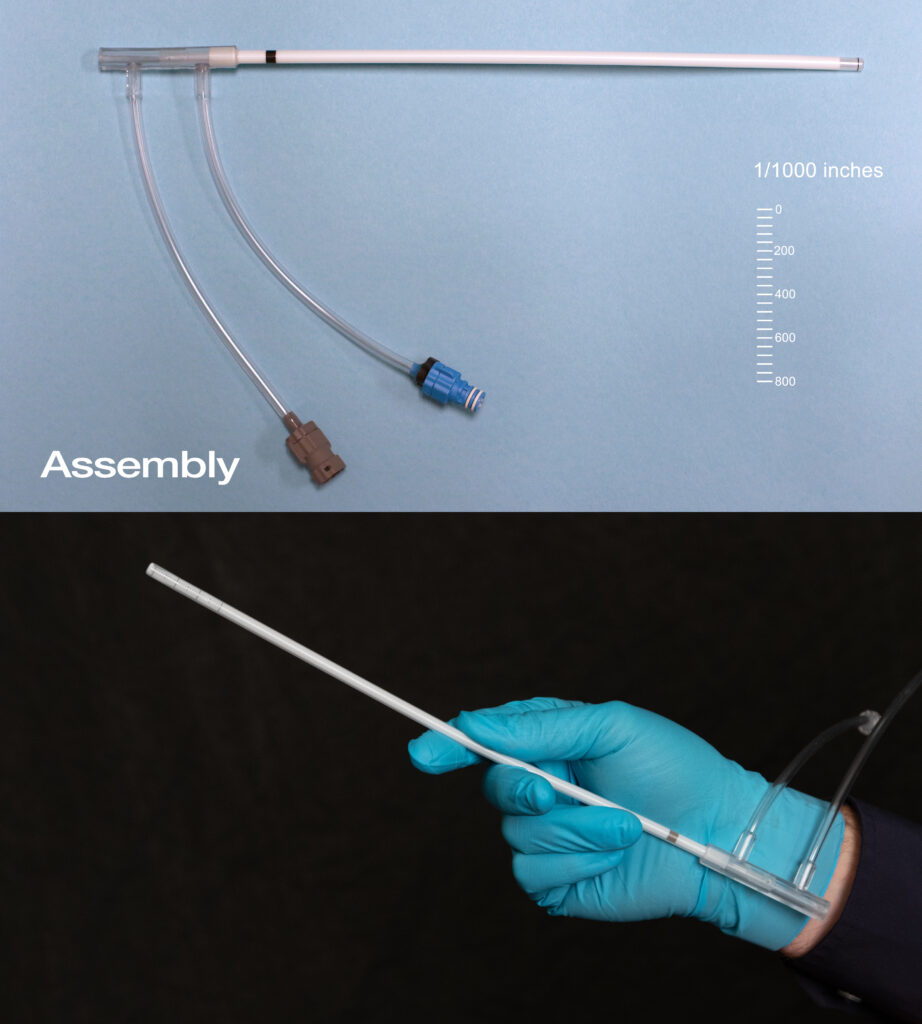

Leak, flow and pressure testing can be performed to ensure the delivery of a well-made product.